With our immersion float switch, our customers can count on maximum flexibility – because the immersion float switch can be easily adjusted to the required switching point height for areas with large measuring ranges.

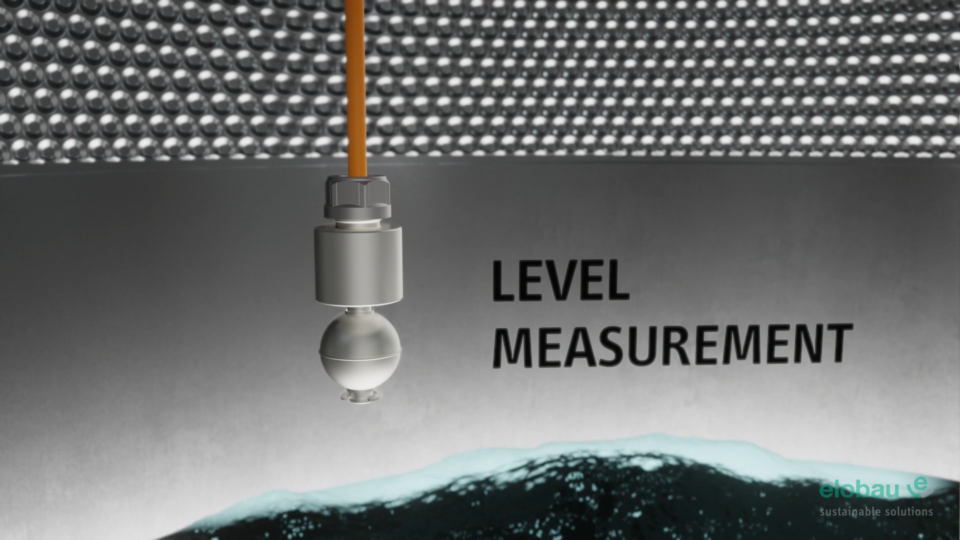

How the immersion float switch works

The float switches are based on robust reed technology and can be attached to the tank opening using threaded sets. They are particularly suitable for monitoring tank applications and for empty and overflow control in process engineering. This also applies to long measuring distances and large containers. The level sensor is suspended from above into the tank and is completely submerged when the tank is full.

You can see how this works in the video:

Up to four immersion float switches can be attached within a single application using the G2 mounting module (No.: 35020502). This allows users to tap several defined switching points in a single application, e.g. 75% fill level + 50% fill level + 25% fill level + empty signal.

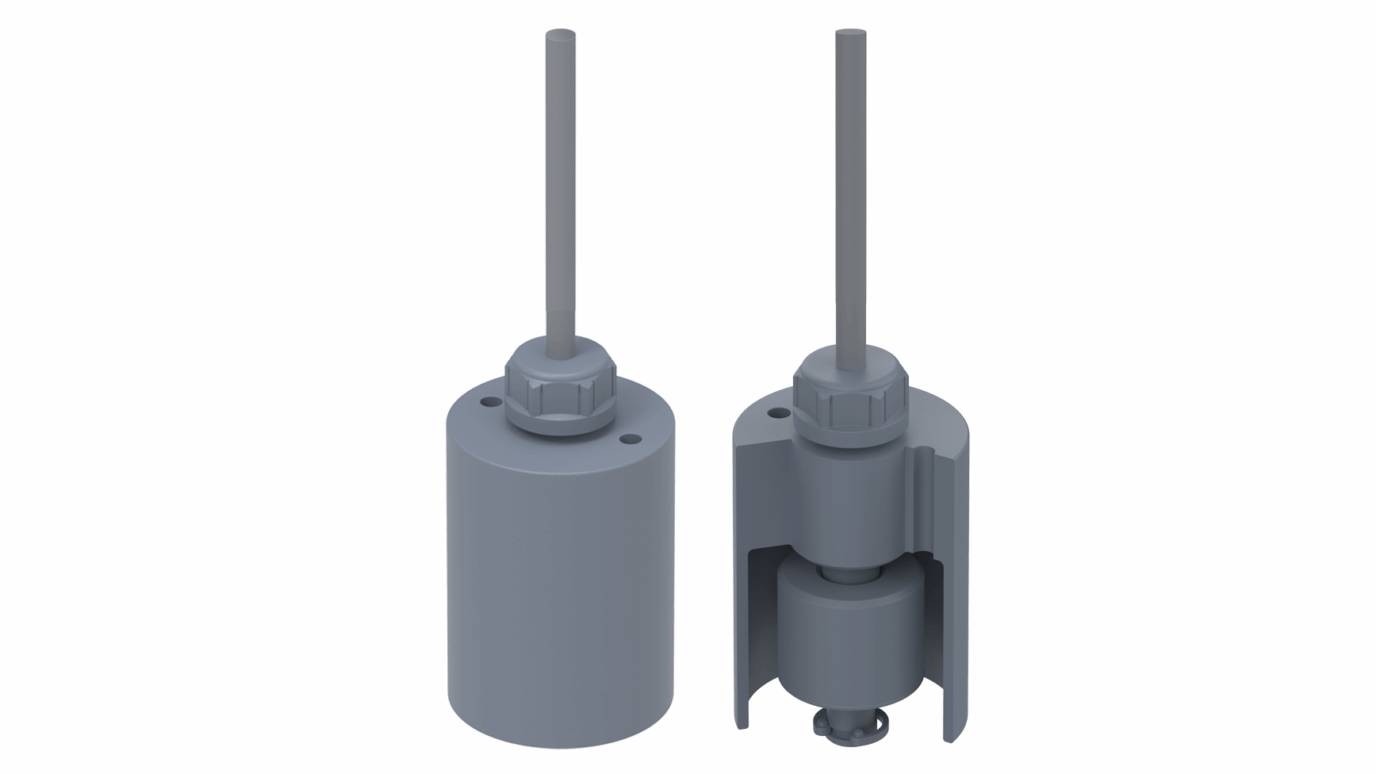

Variants: stainless steel and PVC

Depending on the selected variant (PVC or stainless steel), the immersion float switch from elobau is suitable for measuring the limit level of water, oil and chemicals. With reed technology, protection class IP68 (DIN EN 60529), switching voltages of up to 48 V and a temperature range from -40 °C to +90 °C (stainless steel float switch) and -10 °C to +65 °C (PVC float switch), the level sensor meets the most common requirements in industrial applications. Thanks to its universal design and flexible switching points, a wide variety of float switches are no longer required. Part number variants can be significantly reduced, optimising set up costs, storage space and after market requirements.

Comments

write a comment